Rumored Buzz on Plastic Extrusion Profiles

or today. Genplex has the capabilities to extrude all kinds of plastic (tubing, sheet, profiles), and can personalize our plastic extrusions to satisfy almost any kind of application needs. Whether the plastic tubing dimensions or extrusion forms you need are easy or complex, our team can assist you with design, product option, secondary procedure requirements as well as various other referrals (custom extrusion manufacturer).

Over 60 years later on, we have expanded from this solitary line to 16 extruders. We have the experience as well as knowledge to create and supply quality components on time, every time. Our highly-rated customer support, 99. 9% on-time shipment price and also 99. 8% part approval rate permits us to be the perfect production companion.

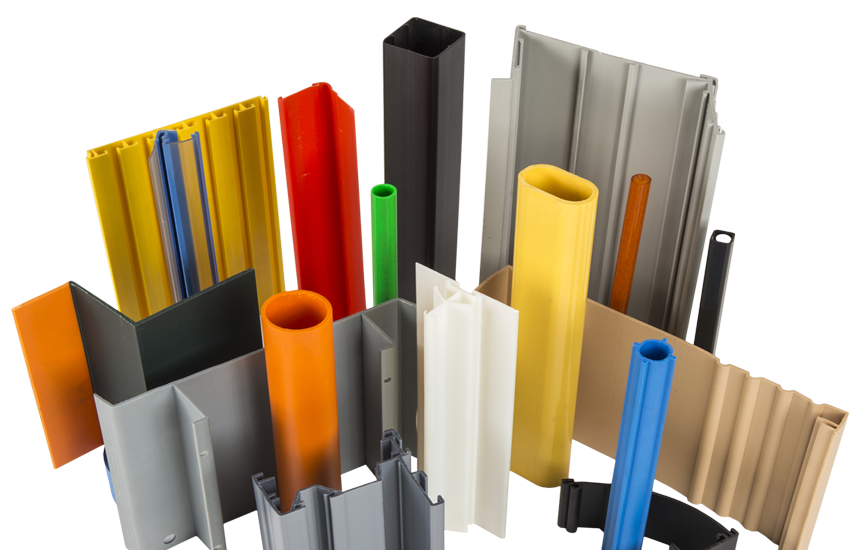

The designed product then feeds onto a conveyor belt, where it experiences a cooling procedure, generally from a sizer, until it requires to undergo additional handling, such as being reduced to size - custom plastic extrusion manufacturers. Plastic extrusion can be formed into lots of forms. Some of one of the most common are tubes, poles, as well as specialty profiles.

The tooling made use of for extrusion procedures is often much less costly than the tooling used during various other plastic manufacturing operations. Co-extrusion makes use of 2 or even more extrusion units to feed different materials via a solitary die head.

Getting My Plastic Extrusion Manufacturers To Work

Preferred Plastics is an industry-leading custom plastics extruder offering turnkey extrusion capacities and ending up solutions. Over the previous 40 years, we have gained an international credibility for squeezing out top notch plastic components to one of the most rigorous specifications - plastic extrusion profiles. Our cutting-edge extruding capabilities are sustained by premium customer support and a dedication to producing parts that fulfill the best requirements as well as are supplied on schedule and on spending plan.

Plastic extrusion is continuous and also with the ability of high volume output, making it an extra affordable plastics making method than various other procedures. Additionally, tooling costs are relatively low. Plastic extrusion works particularly well for the manufacturing of plastic components that have constant wall thicknesses, as well as for accounts that are wider and longer than those created by other kinds of production.

We are here to resolve any kind of extrusion difficulty you may run right into by offering the best squeezed out parts on the marketplace. Call Plastic Extrusion Technologies to get started today!. plastic extrusion companies.

By using this site you agree to this Privacy Policy. Learn how to clear cookies here

Amarys Gabernet's Epic Misadventures: A Tail of Laughter and Calamities Preikestolen: Naturens betagende kunstværk శాంతియుత యోధుడు ముష్ఫికర్ రహీమ్ Rosale Dulisz: The Clumsiest Person You'll Ever Meet Rosale Chau Reveals the Best Travel Tips You've Never Heard! Rosale Guerriero's Once-in-a-Dreamy-Lifetime Adventure regenesyzz The Mind Institute Psychotherapy Удары рф по Украине: повреждены 40% энергетической инфраструктуры