What is a Printed Circuit Board (PCB)?

A swiftly emerging PCB era, cut loose those above, is known as published electronics – normally very simple, very low cost, circuits that lessen electronic packaging price to the level that digital answers may be advanced to clear up problems by no means considered before. They are often utilized in electronics for wearable packages, or disposable electronic gadgets – starting many possibilities for creative electrical designers.

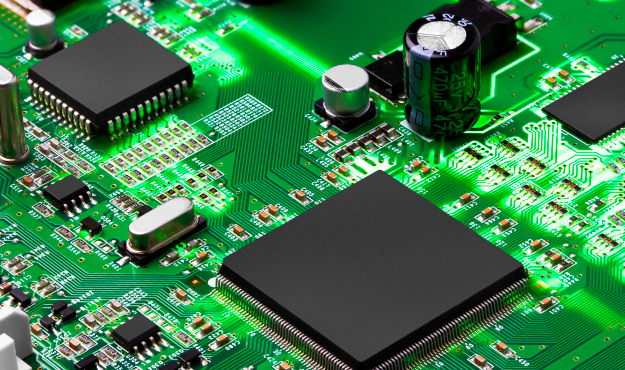

PCB’s had been evolved within the early twentieth century but have had a persevered escalated development in technology considering the fact that then. The advancement and sizeable adoption of technology in PCBs has paralleled the fast development in semiconductor packaging generation and has enabled enterprise professionals to spend money on smaller and extra efficient electronics.

Founded in 1977, Printed Circuits LLC has considering that emerge as a ground-breaking revealed circuit board producer. Originally manufacturing all types of PCB’s, they drove toward specialization in inflexible flex and bendy circuit production in the mid 1990’s. Our large choice of PCB designs, allows us to serve a wide range of industries around the sector, together with military, scientific, aerospace, pc, telecommunications, and instrumentation. Here we offer a comprehensive evaluate of published circuit forums to offer applicable heritage information for what we do.

Why Are Printed Circuit Boards Used?

Compared to standard stressed circuits, PCBs offer a number of benefits. Their small and light-weight design is suitable to be used in many present day gadgets, while their reliability and simplicity of renovation in shape them for integration in complicated systems. Additionally, their low cost of manufacturing makes them a highly price-powerful alternative.

These features are a number of the reasons PCBs discover software throughout industries, together with within the following markets:

Medical

Medical electronics have significantly benefited from the advent of PCBs. The electronics in computer systems, imaging systems, MRI machines and radiation system all retain to enhance in technology from the electronic capability in PCB’s.

The thinner and smaller size of flexible and inflexible flex PCBs permits for the manufacture of greater compact and light-weight clinical devices, along with hearing aids, pacemakers, implantable gadgets, and sincerely tiny cameras for minimally invasive strategies. Rigid PCB are a specifically ideal solution when looking to lower the dimensions of complex medical gadgets, as they do away with the need for the flex cables and connectors that take up valuable space in extra tricky structures.

Aerospace

Rigid, flexible and inflexible flex PCBs are generally hired within the aerospace enterprise for instrument panels, dashboards, flight controls, flight management and safety systems. The growing number of advances in aerospace era have expanded the need for smaller, greater complicated PCBs to be used in plane, satellites, drones, and different aerospace electronics. Flexible and inflexible flex circuits offer notable durability and project survivability due to the removal of connectors. This makes them appropriate for use in excessive-vibration applications, whilst their small and lightweight layout reduces the overall gadget weight and, consequently, gasoline consumption necessities. For applications where dependability is paramount, they serve as a exceedingly dependable answer.

By using this site you agree to this Privacy Policy. Learn how to clear cookies here

Thin Content Là Gì? Tất Cả Thông Tin Về Thin Content Cần Phải Biết Roman Kneblewski - nieznany bohater polskiego kina Lutron Lights, Shades and Blinds Installer NYC 關繼威 關繼威:一位好萊塢電影界的華裔領軍人物 鈴木一朗——一個安打製造機的靈魂旅程 Xe Phương Trang: Bến Xe, Giá Vé, Tổng Đài Đặt Vé Các Tỉnh Thành MSL Housecleaning LLC Trang trí trần phòng khách đẹp bằng giải pháp trần xuyên sáng Barrisol